New Blades and Made in Brunel graduate showcases

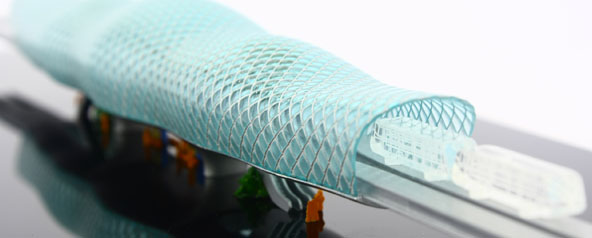

This time of year sees the advent of two significant degree shows; the New Blades Modelmaking degree show and the Made in Brunel graduate showcase. Both are an opportunity for graduates to make invaluable contacts within their industries, to show off their work, skills and passions, and for seasoned professionals to meet young people with fresh eyes and good ideas. The New Blades took place at Holborn Studios and featured some truly outstanding work; the show guide is available for download at the 4D Modelshop website. It is also a chance to meet old friends and former colleagues as the bulk of the UK's model making companies and their representatives meet. The Made in Brunel Graduate Showcase aims to draw the attention of the design industry to a pool of innovative aspiring designers and engineers. This year, former Amalgam intern Jeremy Ireland (https://madeinbrunel.com/) will be showcasing his…