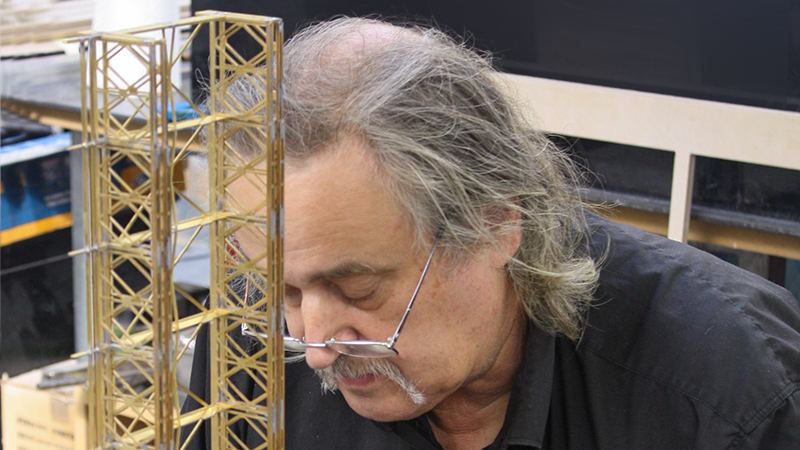

Meet Mike Quarry, one of Amalgam’s engineers working on all sorts of projects. He’s been…

Additive layer manufacturing: From ‘art’ to ‘part’

EEF, the manufacturers’ organisation, in conjunction with Materials and Design Exchange (MaDE), Materials KTN and Exeter University Centre for Additive Layer Manufacturing (CALM) recently held an event at Exeter University to inform businesses in the South West about the range of services and technologies available in the region. The day was organised by Phil Brownsord of EEF and John Bound of MaDE, the Materials and Design Exchange, a part of the Knowledge Transfer Network and featured speakers including Nick Grace from the RCA, Dr. Sara Flint of CALM and Amalgam’s own Mike Harvey. Apart from the various presentations which covered various aspects of Additive Layer Manufacturing and Product Development the day also included a tour of CALM’s impressive facilities with Richard Davies and James Bradbury providing demonstrations of the various processes on site.

Additive layer manufacturing

Often referred to simply as “Additive Manufacturing” or “AM” is a branch of 3D printing – in many cases the terms are interchangeable in fact but whereas 3D printing has been seized upon by the media and often refers to low-cost, low-definition machines that extrude plastic filament. Additive layer manufacturing is generally used to refer to processes used in industry not only to quickly produce so-called “Rapid Prototypes” for test and trial purposes but increasingly as a method of producing end-product items with properties equal to or in some cases better than would be achievable by conventional means.